Technology

SolWo MBC products rely on the latest advancements in the fields of electromagnet-, detector- and industrial automation technology. We set high standards for the overall quality, performance and reliability of our products.

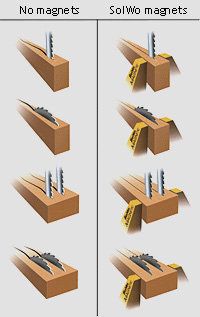

Electromagnets are the core of our MBC technology. After several years of product development we have succeeded in designing magnets which perform to high standards and have optimal durability. Our products must endure severe operating environments and be able to perform at full capacity at the same time.

A modern sawmill is a very challenging environment for equipment based on high technology. Magnetic Blade Control operates based on information from the system's inductive detectors. These detectors must monitor the saw blade position within 0,01 mm accuracy despite sawdust and blade cooling fluids.

Power for our MBC systems comes from standard, automated DC electricity sources. Electric current for the magnetic control system varies depending on the power demand of the magnets.

Control electronics feed power to the magnets using data from the detectors to position and keep the blade on the correct sawing line.

R&D

In SolWo reseach and development computer simulation is used to be able to test and develop functionality out of the sawmill environment. Below is presented the MBC-103 log line simulation running with MBC-103 unit installed on test bench.